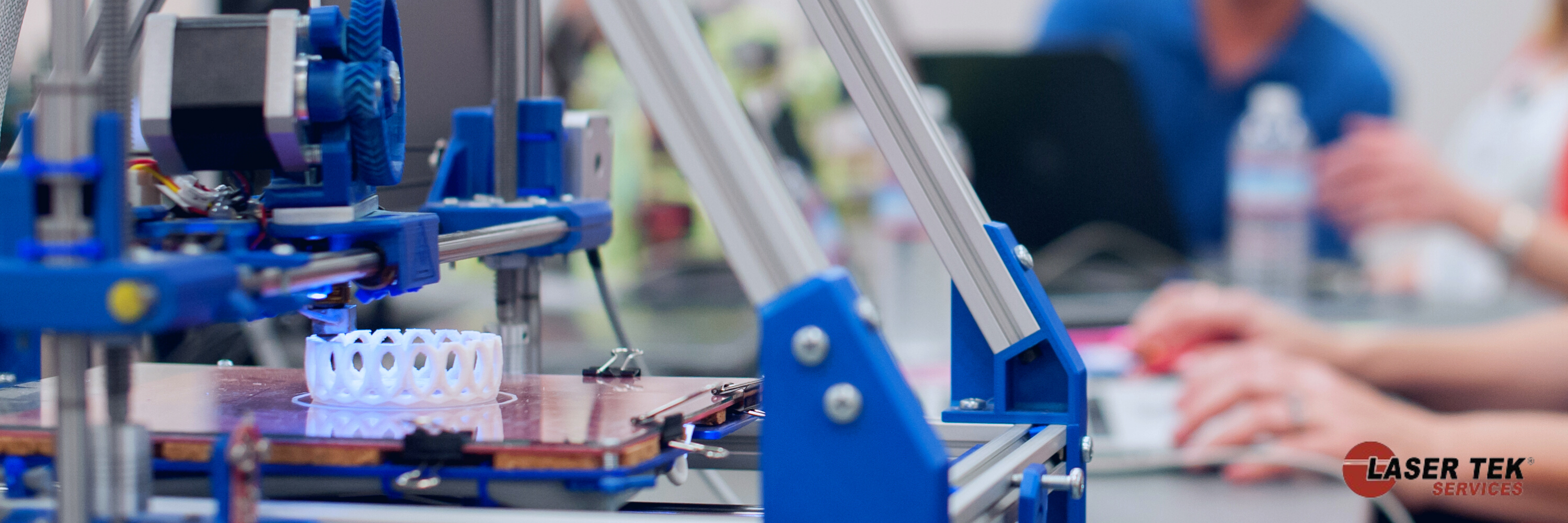

3D printing has vastly improved mass prototyping which used to be a rather difficult phase of product development particularly for smaller startups. Because of the potential that additive manufacturing is showing, the industry became zero to $1.3 billion market value in 2012. However, there are many things it needs improving to be able to take flight and completely redefine manufacturing. These are some important things that are holding back 3D Printing Technology as of now:

Materials

Additive manufacturing or 3D Printing improved tremendously on reduction of material costs this year. But printing expenses are only a leaf in a tree of problems. Most 3D printers today are limited to material of choice which is plastic like ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic Acid) to create shapes as demanded. Such materials work just fine for small prototypes with no working parts. However, they are still too weak to be used to create functioning common household products. They can’t take a lot of pressure causing the whole product to break apart completely.

Get the inside story on the http://www.lasertekservices.com industry from Recycle. Refill. Save!

3D printouts are also In addition to that, different 3D printing technologies use proprietary consumables which only work for a specific 3D printer. You still have to buy a specific material for it to work in tune with your equipment. It is rather vexing, but unfortunately, we can’t do anything about it until 3D Printing Companies decide to standardize the materials.

Machine Range

There many 3D printer types available in the market. Each type of printer has its own perks and drawbacks. The main consumer-level 3D printers are the FDMs. These kinds of 3D printers extrude ABS or PLY plastic in a relatively safe container and the materials cools down quickly to assume a shape or form. The print outs are safe to touch straight from a machine while leaving little to no mess.

This however, is not the same for many other types of 3D printers. For example, 3D printing solutions that use Resins as the main consumable can produce more detailed products. But they are relatively more expensive to run plus they are very messy. Powder-based printers are the most dangerous types as well as messy and are literally explosive. Another 3D printing solution either operate at high temperatures, produce horrible parts or leave an intolerable amount of unrecoverable waste.

3D Models

3D printing is the most practical and economical way of mass prototyping. However, creating a 3D model is not really as simple as everyone expects it to be. You do not only need to learn how to use the CAD program, but you also have to learn how to design a working model. You also need to learn how to fix models yourself to be able to produce a satisfactory output. It really does take a lot of time and skill and trials to create a working CAD model.

Reuse empty toner cartridges and save as much as 80% on printing costs. Visit http://www.lasertekservices.com and shop for the toner refill kit compatible with your cartridge.

There are many 3D model libraries in the internet that you can download for free. However, 99% of the CAD models are either unmoderated or defective and will not be able to produce satisfactory results. Moreover, you can’t really be sure that a downloadable model will work in tune with your 3D printing solution. Most 3D printing technology in the market requires a certain design technique for it to deliver good results. This is also why 9 times out of 10, a single model will not create a quality part of a different 3D printer.