Electrophotographic printing (EP) employed in laser printing technology has emerged as the best option for home and office printing for the past 4 decades and counting. But do you have any idea why EP printing is possible? EP printing is an offshoot of basic electricity that utilizes the positive and negative polarities of direct current (DC) to attract and repel toner in each laser printing sequence. It follows the basic property of magnetism that ‘like poles repel each other and unlike poles attract each other

At the start of the printing cycle, the Organic Photo-Conductor or OPC Drum is cleared of its negative charge by the Primary Charge Roller or PCR to pave the way for the negatively charged raster image projected by the laser scanning assembly. Naturally as the OPC Drum comes in contact with the laser toner cartridge, the positively charged toner particles literally jump into the negatively charged raster image; but not on the positively charged surface of the drum. Because of the action of magnetism, toner particles will cling permanently to the OPC Drum surface and paper/media has to be charged with a higher negative potential to allow the toner particles to transfer to paper.

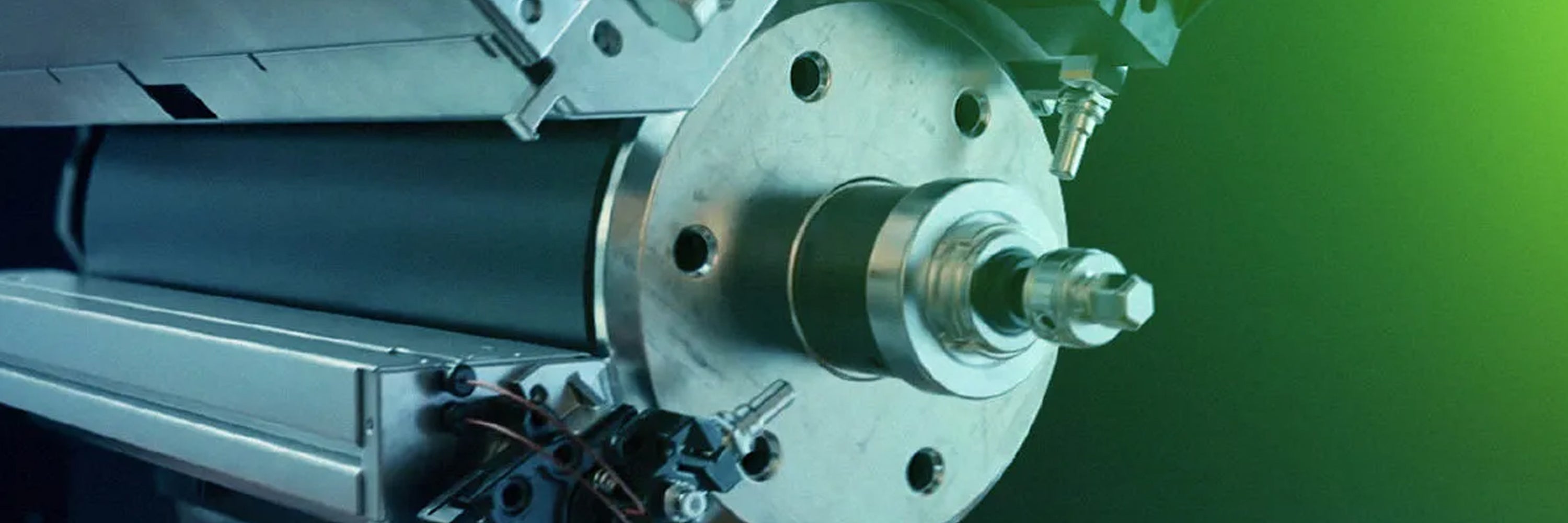

What makes toner particles cling to the OPC Drum and paper/ media in the process of Electrophotographic printing? The obvious answer could only be the magnetite integrated into the toner formulation that makes EP printing possible. Magnetite compose of very minute iron particle or particles that are mixed with toner powder in the course of manufacturing. This gives laser printer toner the ability to respond to varying electrical potential charged into the developer (magnetic) roller that dictates the degree of print density. The greater the electrical potential directed at the magnetic roller, the greater the density of toner powder coming from the laser toner cartridge is dispensed into the OPC Drum surface. Consequently, this results to finer print quality.

Thus, users looking out to minimize laser printer toner consumption can simply adjust toner density setting to economy mode and help extend the print capacity ensuing each toner cartridge load. This special feature is a plus because most of the time, printed documents are for inter-office use only and therefore do not need high density printouts.

The toner density setting actually serves as the printer miser responsible for toner consumption and dictates accrued savings. In the end, the yield capacity of a toner cartridge will depend on office printing activity and not the rating specified by printer manufacturers.

As always, remember that Electrophotographic printing is only possible because of the magnetite integrated into the toner formulation.

Photo by liewcf